10 Benefits of Brazed Plate Heat Exchangers Over Traditional Coil Systems

- Author: Denrie Perez

- Date Posted:

When it comes to efficient heat transfer, not all systems are created equal.

While traditional coil heat exchangers (such as finned tube or serpentine coil designs) have been the industry standard for decades, modern brazed plate heat exchangers (BPHEs) offer a range of compelling advantages, especially in today’s energy-conscious, space-limited, and performance-driven environments.

While traditional coil heat exchangers (such as finned tube or serpentine coil designs) have been the industry standard for decades, modern brazed plate heat exchangers (BPHEs) offer a range of compelling advantages, especially in today’s energy-conscious, space-limited, and performance-driven environments.

What is a Brazed Plate Heat Exchanger (BPHE)?

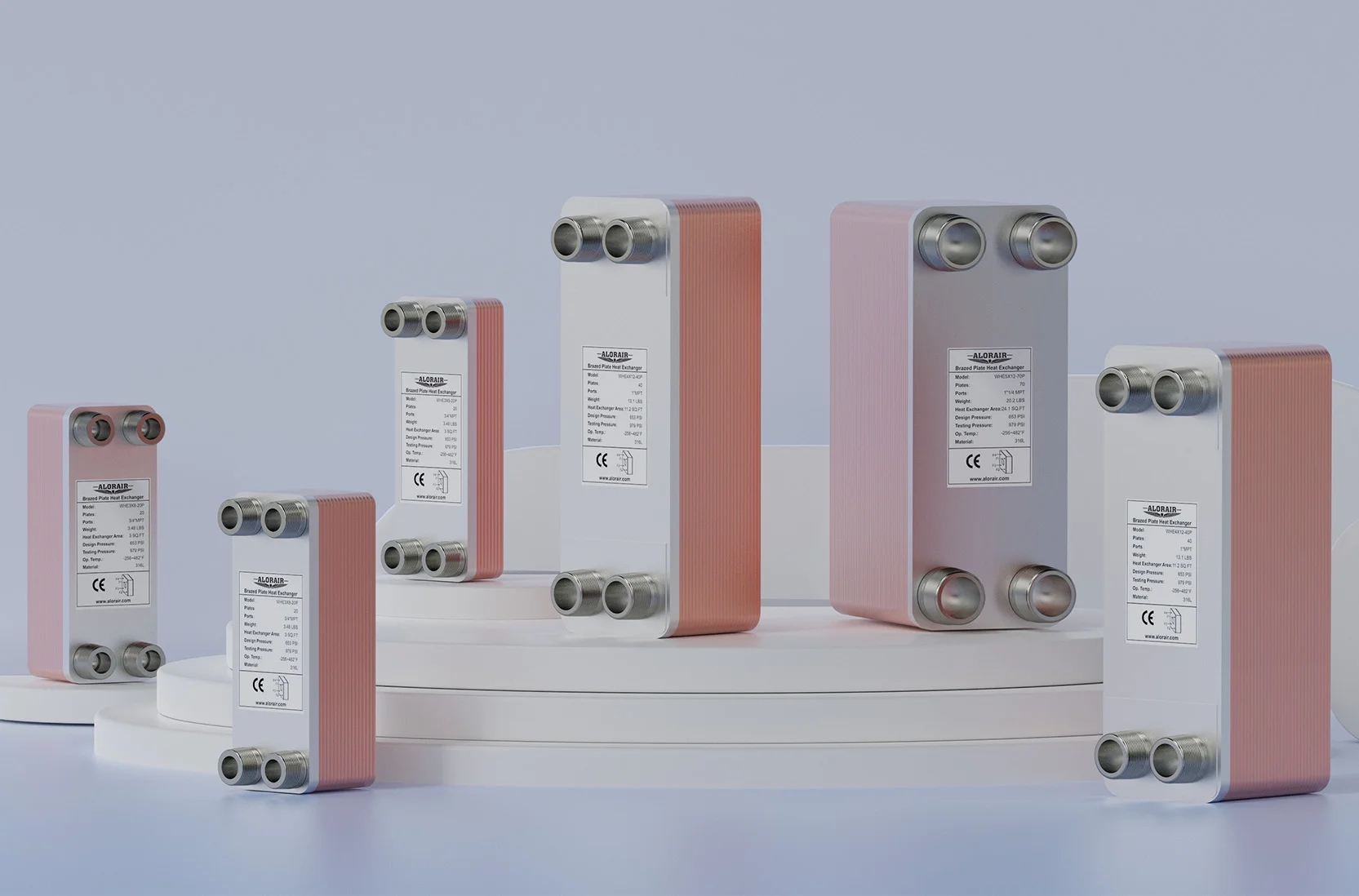

A brazed plate heat exchanger (BPHE) is a compact, high-efficiency tool used to transfer heat between two fluid streams without mixing them. It’s made up of multiple thin, corrugated metal plates stacked together and permanently bonded through a brazing process that often uses copper or nickel.

The alternating flow channels formed between the plates allow hot and cold fluids to pass on opposite sides, maximizing heat transfer through the large surface area and turbulent flow. This efficient thermal exchange happens in a much smaller unit than traditional coil or shell-and-tube systems.

BPHEs are widely used in HVAC systems, refrigeration units, industrial processes, hydronic heating, and renewable energy applications due to their durability, efficiency, and space-saving design.

The alternating flow channels formed between the plates allow hot and cold fluids to pass on opposite sides, maximizing heat transfer through the large surface area and turbulent flow. This efficient thermal exchange happens in a much smaller unit than traditional coil or shell-and-tube systems.

BPHEs are widely used in HVAC systems, refrigeration units, industrial processes, hydronic heating, and renewable energy applications due to their durability, efficiency, and space-saving design.

Why Heat Transfer Efficiency Matters

When heat transfer efficiency is low, the system suffers—and so does your bottom line. Here are challenges that result from inefficient coil-based heat exchange systems:

Increased Energy Consumption

Inefficient heat exchangers force HVAC systems, chillers, or boilers to work harder and run longer, consuming more energy than necessary. This drives up utility costs, especially in commercial or industrial settings where climate control is critical year-round.

Poor Temperature Control

Slow or uneven heat transfer leads to unstable temperatures. Whether it’s a manufacturing process or a multi-zone building, poor thermal regulation means inconsistent comfort, lower product quality, or even system downtime.

Bulky Equipment

Traditional coil systems often require bulkier units to compensate for lower efficiency. This not only eats up valuable mechanical room or rooftop space but can also complicate installation, limit future upgrades, and increase overall system cost.

Frequent Maintenance & Fouling Issues

Coils with wide, exposed surfaces are prone to clogging, corrosion, and fouling—especially in dirty or high-demand environments. This leads to frequent cleaning, performance loss, and unexpected repairs, disrupting operations and increasing maintenance overhead.

System Strain and Shortened Lifespan

When your system has to overcompensate for poor heat transfer, critical components like compressors and pumps experience accelerated wear and tear. This results in higher failure rates, costly downtime, and premature equipment replacement.

Benefits of Brazed Plate Heat Exchangers

Whether you’re designing HVAC systems, managing an industrial process, or engineering a compact thermal solution, here are 10 reasons why a brazed plate heat exchanger might be the smarter choice over traditional coil systems.

- Superior Heat Transfer Efficiency Brazed plate heat exchangers are engineered with thin, corrugated metal plates that create high turbulence in the fluid streams. This turbulence significantly improves the thermal exchange rate, allowing BPHEs to transfer more heat in a smaller footprint compared to coils.

- Space-Saving, Compact Size BPHEs are extremely compact compared to coil systems. This makes them ideal for installations where space is limited, such as in modular HVAC units, mobile systems, or small mechanical rooms.

- Lightweight Construction Thanks to their efficient plate design and brazing process, BPHEs are lighter than bulky coil systems. Lighter weight means easier transportation, faster installation, and reduced structural load, which is a major plus in retrofit or rooftop applications.

- Wide Operating Pressure and Temperature Range Thanks to their all-metal, brazed construction, BPHEs can handle high pressures and extreme temperatures well beyond the tolerances of most coil-based exchangers. This makes them suitable for demanding applications like refrigeration, steam systems, and high-rise HVAC.

- Minimal Maintenance Requirements Unlike coils that can trap dirt and debris in wide fin spacing, BPHEs have smooth stainless steel plates that resist fouling. Plus, without gaskets or moving parts, there’s less risk of mechanical failure over time.

- No Need for Fans or External Power Traditional coil systems often require airflow via fans for heat transfer. BPHEs work purely on fluid movement, with no need for blowers or electrical components, making them more energy-efficient and quieter in operation.

- Leak-Free Performance Coil systems rely on mechanical joints and bends that are vulnerable to leaks. BPHEs, by contrast, use vacuum brazing to permanently seal the plates together, creating a durable, leak-resistant structure that performs under high pressure.

- Versatility Across Applications From residential HVAC and hydronic heating to industrial cooling, refrigeration, and industrial processing, BPHEs are adaptable to a wide range of applications, handling everything from water and glycol to refrigerants and corrosive fluids.

- Improved System Responsiveness The design of BPHEs allows for rapid heat transfer with minimal thermal lag. This makes them ideal in systems that require fast temperature control or on-demand heating/cooling cycles.

- Cost-Efficient Over Time BPHEs deliver lower lifetime costs through improved thermal efficiency, fewer breakdowns, and reduced energy consumption.

Upgrade to AlorairCoil Brazed Plate Heat Exchangers

If you’re still relying on bulky, outdated coil systems, it’s time to make the switch to performance-driven technology. AlorairCoil’s brazed plate heat exchangers are engineered for professionals who demand more—from efficiency to durability and design.

Built for Performance Under Pressure

Each unit is constructed from 316L stainless steel plates and vacuum-brazed with copper, offering unmatched resistance to corrosion, high temperatures, and structural stress. This design ensures leak-free performance, even in aggressive operating conditions.

Up to Increased 99% Heat Transfer Efficiency

Ultra-thin stainless steel plates promote rapid and even heat exchange, reducing system strain while boosting both heating and cooling cycle efficiency.

Additionally, our advanced fishbone pattern maximizes turbulence while minimizing pressure drop, achieving up to 99% greater heat transfer efficiency compared to traditional coils.

The result? Faster heat exchange, lower energy use, and enhanced system responsiveness.

Additionally, our advanced fishbone pattern maximizes turbulence while minimizing pressure drop, achieving up to 99% greater heat transfer efficiency compared to traditional coils.

The result? Faster heat exchange, lower energy use, and enhanced system responsiveness.

Compact and Seamless Integration

Smooth-threaded connectors and a modular, space-saving form allow for fast, hassle-free integration into new or existing systems, minimizing setup time and system downtime.

Versatile Fluid Compatibility

AlorairCoil’sbrazed plate heat exchangers are engineered to work with a wide range of fluids, including industrial water, high-viscosity liquids, mildly corrosive chemicals, fiber-laden media, pharmaceutical-grade fluids, vapors, and gases.

Explore our range of products and optimize your thermal performance today with AlorairCoil.

Conclusion

Other Posts You Might Like

10 Benefits of Brazed Plate Heat Exchangers Over Traditional Coil Systems

Denrie Perez

04/11/2025

When it comes to efficient heat transfer, not all systems are created equal. While traditional coil heat exchangers (such as […]

The Science Behind Heat Transfer in Brazed Plate Heat Exchangers

Denrie Perez

04/11/2025

In industrial and commercial applications, the need for high-efficiency heat exchange systems is ever-growing. Brazed plate heat exchangers have become […]

Brazed vs. Gasketed Heat Exchangers: What’s the Difference?

Denrie Perez

04/10/2025

Efficient thermal management is key to ensuring system performance and reliability. At the heart of many thermal control systems lies […]