Automotive Oil Cooling

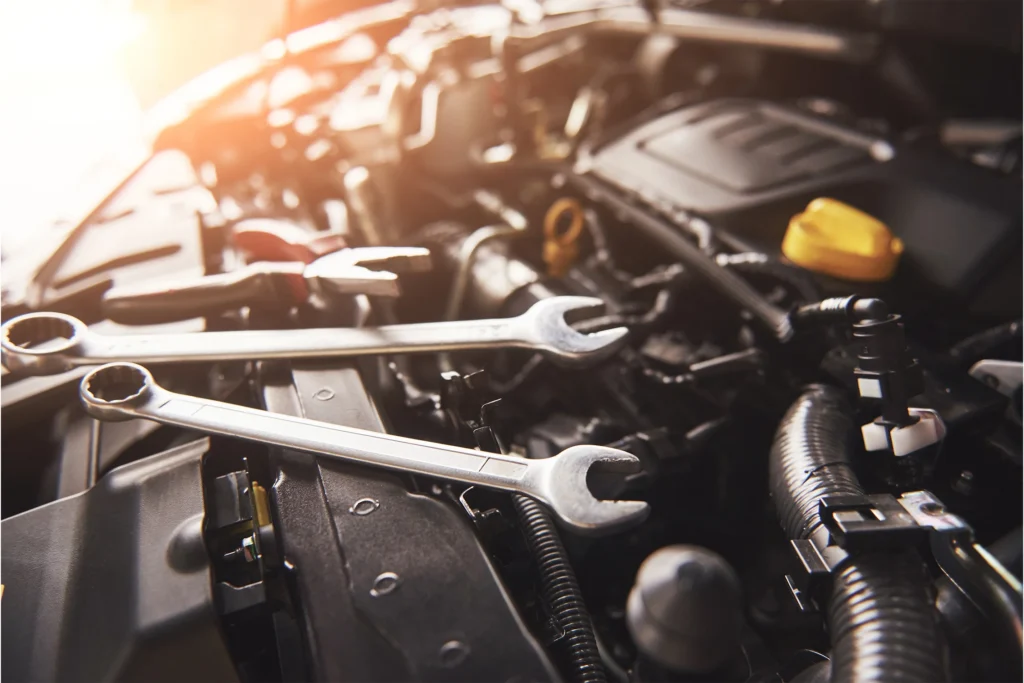

In high-performance and heavy-duty automotive applications, maintaining optimal oil temperature is crucial for engine efficiency, transmission longevity, and overall vehicle reliability. Excess heat buildup in oil can lead to reduced lubrication effectiveness, increased component wear, and potential system failures.

What are Brazed Plate Heat Exchangers (BPHEs)?

Brazed plate heat exchangers (BPHEs) are designed to transfer thermal energy between two fluids without direct contact. They consist of multiple thin, corrugated metal plates brazed together, forming parallel channels through which the fluids flow. The corrugation enhances turbulence, significantly improving heat transfer efficiency.

The Role of BPHEs in Automotive Oil Cooling

Applications of BPHEs in Automotive Systems

- Engine Oil Cooling – Helps regulate engine oil temperature, preventing thermal breakdown and reducing wear on engine components.

- Transmission Oil Cooling – Maintains transmission fluid at optimal temperatures, improving gear shifting and prolonging transmission life.

- Hydraulic System Cooling – Essential in heavy-duty vehicles and construction equipment to prevent hydraulic fluid overheating.

- Turbocharger Cooling – Enhances turbocharger efficiency by managing excess heat from lubrication and boost pressure systems.

Challenges in Automotive Oil Cooling

Excessive heat causes oil to degrade faster, reducing its lubricating properties and increasing internal friction.

High oil temperatures accelerate wear on engine bearings, pistons, and transmission gears, leading to costly repairs and shorter service life.

Advantages of AlorairCoil’s BPHEs in Automotive Oil Cooling

AlorairCoil’s BPHEs are designed with a fishbone corrugated plate pattern that promotes turbulence and accelerates thermal exchange. This results in up to 99% heat transfer efficiency, ensuring oil temperatures are quickly stabilized, even under demanding conditions.

BPHEs are significantly smaller and lighter than traditional heat exchangers, making them ideal for space-constrained automotive applications.

AlorairCoil BPHEs offer powerful cooling capacity in a slim, space-saving profile. Their vertical mounting flexibility and lightweight construction allow for seamless integration into tight engine bays or transmission assemblies.

Automotive environments expose components to extreme vibrations, pressure spikes, and thermal cycling.

AlorairCoil’s BPHEs are constructed from corrosion-resistant SS316L stainless steel and vacuum-brazed with copper, forming strong, uniform bonds that can withstand high operating pressures. This robust construction ensures reliable, leak-free operation in even the harshest road and track conditions.

This leads to longer service intervals, reduced maintenance requirements, and lower overall ownership costs, making them a smart, long-term solution for critical oil cooling applications.

Choosing the Right BPHE

Load Capacity

Calculate the amount of heat transfer needed to ensure that the heat exchanger is capable of handling the required thermal load and maintain system efficiency.

Operating Temperatures and Pressures

Choosing a BPHE with the appropriate tolerance ensures safe and efficient operation while preventing potential failures due to extreme conditions.

Fluid Type and Flow Rates

The type of fluid being processed the heat exchanger’s flow rate capacity affects the performance and longevity of the BPHE.

Material Compatibility

Material selection is vital to prevent corrosion and degradation, particularly with highly aggressive or specialized fluids that may require alternative configurations.

Available Space

Ensuring proper clearance for connections and maintenance access can prevent operational issues and facilitate easy integration into the system.

Conclusion

Brazed plate heat exchangers are a crucial component in modern automotive oil cooling systems, offering superior thermal performance, compact design, and long-term reliability. Whether for engine, transmission, or hydraulic oil cooling, AlorairCoil’s BPHEs provide an efficient and durable solution for maintaining optimal vehicle performance.